Optical Glass Cutting Machines: Precision Redefined

Vimfun Optical Glass Cutting Machines use advanced diamond wire technology to cut sapphire, laser optics, and more — cleaner, thinner, and faster than ever

N . A . Office

Winnipeg, MB, Canada

Call Us

(1)408-571-8651

7:30 AM - 7:30 PM

7 days

WHAT WE DO

Precision Solutions with Optical Glass Cutting Machines

We specialize in the design and manufacturing of diamond wire cutting machines engineered for optical glass, sapphire, quartz, and other brittle or transparent materials.

Our cutting machines offer clean, chip-free slicing, support CNC automation, and are optimized for high-precision, low-dust production environments.

Whether you're cutting lenses, prisms, wafers, or optical substrates, our solutions ensure superior clarity, flatness, and consistent reliability.

Free Sample Cut

We provide free sample cut if you send workpiece and drawing

Machine Design

Design machines for your specific Cutting needs

Consumables

Offer all essential consumables for a smooth machine operation

CUTTING MACHIES WE OFFER

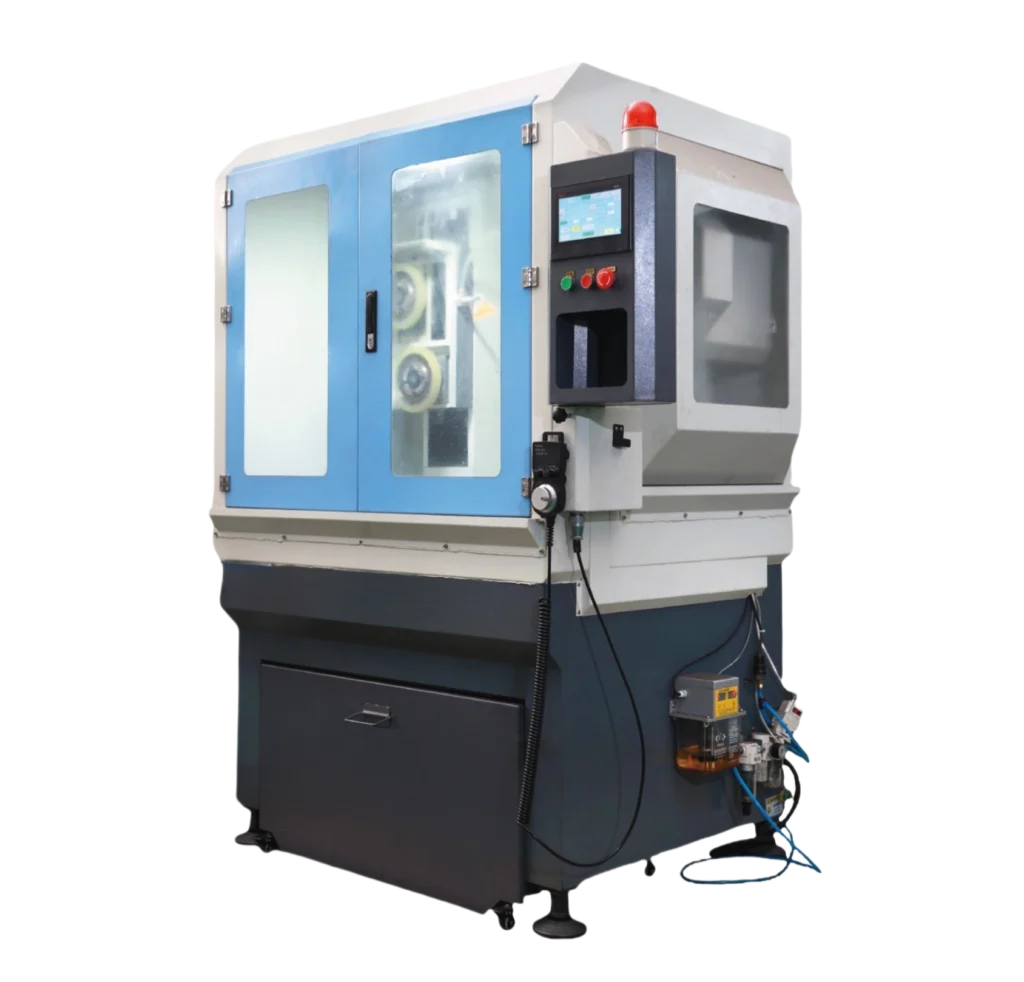

Explore Our Glass Cutting Machines

- Max Workpiece Length (mm): 200

- Max Workpiece Width (mm): 200

- Max Workpiece Height (mm): 200

- Wire Diameter (mm): 0.3 – 3.5

- Wire Length (mm): 700 – 10000

- Wire Diameter (mm): 0.3 – 3.5

- Wire Length (mm): 700 – 10000

- Wire Diameter (mm): 0.3 – 3.5

- Wire Length (mm): 700 – 10000

- Max Workpiece Length (mm): 1800

- Max Workpiece Width (mm): 900

- Max Workpiece Height (mm): 900

- Max Workpiece Length (mm): 400

- Max Workpiece Width (mm): 400

- Max Workpiece Height (mm): 350

- Max Workpiece Length (mm): 200

- Max Workpiece Width (mm): 200

- Max Workpiece Height (mm): 200

- Max Workpiece Length (mm): 400

- Max Workpiece Width (mm): 400

- Max Workpiece Height (mm): 350

- Max Workpiece Length (mm): 200

- Max Workpiece Width (mm): 200

- Max Workpiece Height (mm): 200

- Max Workpiece Length (mm): 200

- Max Workpiece Width (mm): 200

- Max Workpiece Height (mm): 200

- Wire Diameter (mm): 0.3 – 3.5

- Wire Length (mm): 700 – 10000

MATERIALS WE CUT

Optical Glass Cutting Machines: Applications Across Optical Industries

Our Optical Glass Cutting Machines are trusted by manufacturers, research laboratories, and precision optical suppliers across various high-tech industries. Whether you're focused on mass production or prototyping, our cutting solutions deliver clean, accurate, and efficient results for brittle and transparent materials.

Lens Windows Cut

Ideal for lens windows and high-precision components.

Cutting 0.3mm blue optical filter glass with clean edges and no chipping

Check Machine

Astronomical Optics Pre-Cut

Cutting thick glass substrates used in telescope and observatory optics.

Check Machine

Infrared Night Vision Goggles

Ultra-precise Cut of germanium glass used in infrared lenses for night vision goggles, thermal scopes, and IR optical sensors.

Check Machine

Sapphire Cut

Stress-free cutting of large synthetic ruby crystals used in laser cavities, infrared windows, and mechanical components.

Check Machine

Quartz Rod Cut

Precisely slice quartz blocks into smooth, chip-free cylindrical rods, ideal for light guides, fiber optic preforms, and infrared transmission components.

Check Machine

Ultra-Thin Sapphire Wafer Cutting

Slices sapphire into ultra-thin wafers as thin as 0.2mm, enabling high-precision applications in IR optics, laser protection, and sensor covers.

Check Machine

Precision Prism Block Cutting

Manufacturing prisms, beam splitters, and retroreflectors, especially from BK7, fused silica, and other optical-grade materials.

Check Machine

Glass Angle Cut

Custom angle or bevel cutting for shielding windows used in aerospace and medical equipment.

Check Machine

ABOUT US

Why Our Cutting Is Better

Cutting optical materials isn’t just about separating pieces — it’s about preserving clarity, minimizing stress, and maximizing yield.

Our machines use endless diamond wire cutting technology, which offers clear advantages over traditional blade, saw, or abrasive methods.

🔹 Chip-Free Edge Quality

🔹 Ultra-Smooth Surface Finish

🔹 Minimal Kerf Loss

🔹 Low Cutting Stress

🔹 Supports Thin and Hard Materials

🔹 Cleanroom-Compatible Operation

NEWS & INSIGHTS

Stay ahead with expert

Explore in-depth articles on optical material processing, cutting techniques, and application-specific challenges.